VMAC, a Nanaimo-based manufacturer, has turned a decades-old prototype into a ready-to-sell product. The firm is known for its vehicle-mounted air compressors and complex air systems. Now it offers a simple device for service vans and trucks. The multi-port air manifold lets users link up to four air tools at once.

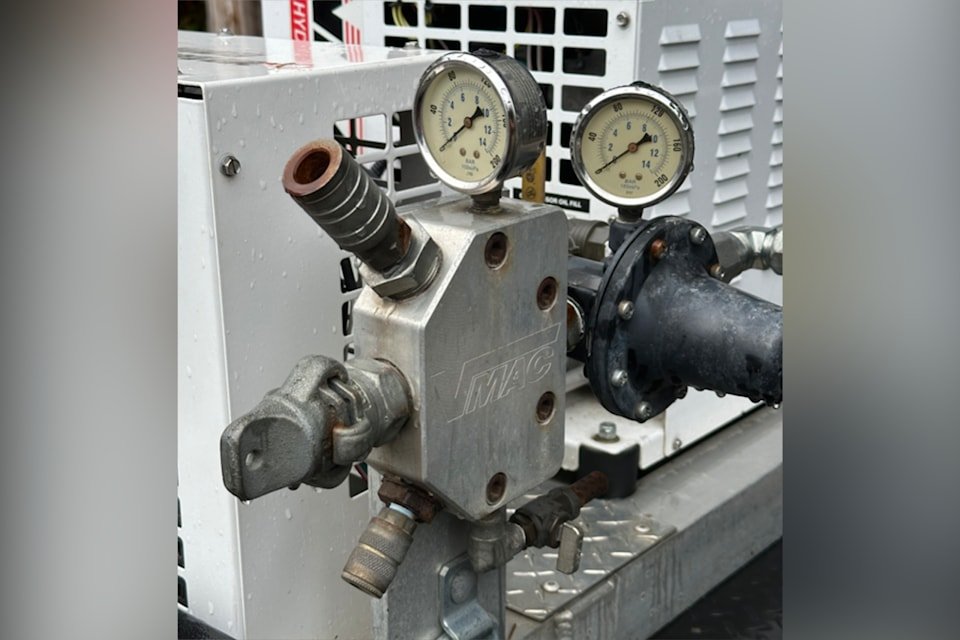

The block is made of machined aluminum. It has four quick-connect fittings. Two are automotive style. Two are industrial style. This mix covers many hose sizes and tool types. It works with impact wrenches, jackhammers, and common air tools. The manifold handles up to 185 cubic feet per minute of air flow. It also withstands up to 200 pounds per square inch of pressure.

A manual ball valve lets operators safely vent pressure. An analog gauge shows real-time air pressure. This makes it easy to monitor and control the setup. No more fumbling with adapters or swapping fittings. Users can switch tools in seconds. This convenience cuts downtime and boosts output on job sites.

The idea traces back over 20 years. Mike Pettigrew, VMAC’s marketing manager, said the firm used a custom manifold on demo trucks. “Our reps drove across North America with demo rigs,” he wrote in email. “They needed to test customers’ tools fast. We built a manifold to swap between wrenches and hammers.” Dealers loved the setup and asked for their own.

“At first, we had no plan to sell it,” Pettigrew said. “But demand grew. We knew it was time.”

Idjen Cabral, a VMAC mechanical engineer, noted similar adapters exist. “It’s not a new concept,” Cabral said. “But we never offered it. Now we see clear demand. It fits our lineup.”

The device joins VMAC’s existing products in its compressed-air portfolio. It targets mobile service teams in construction, road repair, fleet maintenance, and emergency repair services. Firms in these fields often carry multiple air tools. They handle fast repairs and tight deadlines. A manifold cuts the need to carry extra connectors or adapters.

Service truck builders can mount the block on interior walls or tool racks. The package weighs under five pounds. It fits neatly in tight spaces. It uses standard mounting holes and fittings. This eases installation and retrofits on existing rigs. VMAC offers mounting kits and installation guides with each unit.

Early testers report big gains. One contractor said his crew saved 20 minutes per call. They no longer hunt for the right fitting. Another said tool swaps dropped from five steps to one. This cut stress and spares fittings from repeated wear. Mechanics also mention fewer air leaks. Quick-connect fittings seal tightly. This improves tank efficiency and cuts fuel use or generator load.

VMAC expects to roll out the manifold in North America this fall. It plans to add European and Asia-Pacific markets by early next year. Pricing will reflect small-batch machining and precision fittings. Dealers can buy direct or through distributors. VMAC also offers custom colors and laser-etched branding for large orders.

Industry observers see the move as savvy. It makes use of an existing design and fills a clear need. It also broadens VMAC’s reach into simpler, high-volume items. “It shows VMAC can do both complex and basic tools well,” said one analyst. “That builds trust in the brand.”

VMAC says it will gather user feedback to refine future versions. Possible upgrades include gas-assist quick-disconnects and integrated regulators. The company also weighs adding gauges for individual ports. For now, the simple multi-port air manifold meets demand for fast switching and uptime on the job.